The link between Maintenance Costs and Reliability

The maintenance cost factor matrix

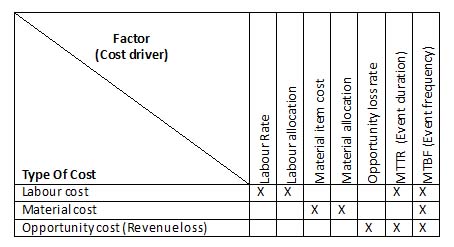

The table below identifies the types of maintenance costs and their drivers

The maintenance cost factor matrix

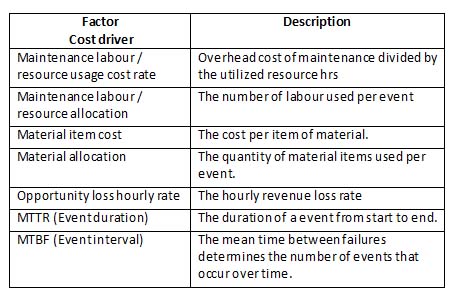

The table below identifies some maintenance cost drivers

Reliability: The common factor that drives maintenance costs

It is noteworthy that in the maintenance cost factor matrix that MTBF is a common cost factor or otherwise put, it is a driver for all three types of maintenance related costs. It is therefore no surprise that equipment reliability improvement should always be a focus area but even more so in the lean times.

The selection of appropriate failure management tactics can no longer be left to chance so it is imperative that organisations faced with reducing maintenance costs pay attention to this important aspect.

Maintenance tactics to sustain or improve reliability

Maintenance tactics should be developed and implemented using an analytical process that anticipates failures that may happen in the future with the aim to predict, prevent, detect or as a last resort to tolerate equipment failure. Some organisations might also have already put plans in place for the execution of corrective maintenance to repair failure and degradation that has occurred or is about to occur. The decision about which specific tactic to apply should be based on a rational process that includes:

- An assessment of the effects and consequences to determine the unmitigated risk of the event.

- An understanding of the deterioration mechanism that causes the event

- An understanding of failure-age relationship.

- The selection of a failure management tactic that is most cost effective to reduce or maintain the risk to a level that is tolerable for the organisation.

Failure analysis to improve reliability

Having well developed failure management tactics does not guarantee a failure free future. Unforeseen human actions underlie most of the unanticipated failure modes. It is therefore imperative if we are serious about reducing costs that we also apply appropriate analysis and to determine the underlying causes of these failures and then applying improvement actions at one or more of the following:

- Improve the asset’s resistance or tolerance to failure

- Improve the reliability of the human by upgrading skill, changing attitudes, changing behavior

- Improve the environment in which people work by improving supervision, proper procedures with quantifiable work standards, discipline, over inspection, tools, etc

Expanding on the maintenance tactics process

In the next session we will take a closer look at the tactics development and failure analysis process.